Sheeters and laminators for cracker production lines from Reading Bakery Systems play crucial help ensure the quality and consistency of the final product. These machines are essential for shaping the dough and creating the distinctive texture and layers that define various types of crackers. Understanding their functions, advantages, and integration into production lines can help manufacturers optimize their processes and achieve superior results.

The Role of Sheeters in Cracker Production

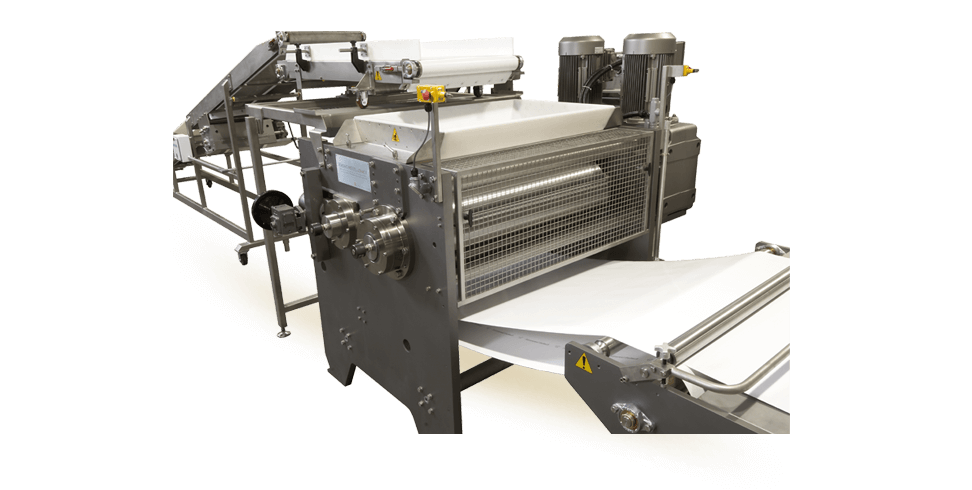

Sheeters are machines designed to roll out dough to a specific thickness, which is a critical step in the production of crackers. The sheeter ensures uniform thickness and texture, which is essential for consistent baking and product quality. Here’s how RBS sheeters contribute to cracker production:

- Uniform dough thickness: Sheeters produce dough sheets of uniform thickness, which is vital for even baking. Consistent thickness ensures that all crackers bake at the same rate, preventing overcooking or undercooking.

- Efficiency: Automated sheeters increase production efficiency by rolling out large quantities of dough quickly and accurately. This automation reduces labor costs and increases production speed.

- Versatility: Modern sheeters can handle a variety of dough types, including those with different moisture contents and ingredient compositions. This versatility is essential for producing different types of crackers, from thin and crispy to thick and hearty.

The Role of Laminators in Cracker Production

Laminators work hand-in-hand with sheeters to enhance the texture and structural integrity of crackers. Laminators create multiple layers of dough, which contribute to the flaky and crispy texture characteristic of many crackers. Here’s how laminators function in the production line:

- Layer creation: Laminators fold and layer the dough, incorporating air between the layers. This process is critical for creating the light, flaky texture found in many premium crackers.

- Texture enhancement: By creating layers, laminators improve the texture and mouthfeel of the final product. The layering process allows for better expansion during baking, resulting in a more appealing texture.

- Customization: Laminators can be adjusted to create varying numbers of layers, allowing manufacturers to produce a wide range of cracker styles and textures. This flexibility is crucial for meeting diverse consumer preferences.

Integration into Production Lines

Sheeters and laminators are integral parts of modern cracker production lines. Their integration involves careful planning and coordination with other machinery, such as mixers, cutters and ovens. Here are key considerations for integrating sheeters and laminators into production lines:

- Compatibility: Ensuring that sheeters and laminators are compatible with existing equipment is essential. This includes matching speeds, aligning conveyor systems, and ensuring smooth transitions between machines.

- Automation: Modern production lines often feature high levels of automation. Integrating automated sheeters and laminators from RBS can streamline the production process, reduce manual labor and enhance consistency and quality.

- Maintenance and hygiene: Regular maintenance and strict hygiene practices are vital for the smooth operation of sheeters and laminators. Ensuring these machines are easy to clean and maintain can prevent downtime and ensure product safety.

Advantages of Advanced Sheeters and Laminators

Investing in advanced sheeters and laminators offers several advantages for cracker manufacturers:

- Improved product quality: Advanced machines ensure precise control over dough thickness and layering, resulting in high-quality crackers with consistent texture and appearance.

- Increased efficiency: Automation and advanced technology reduce production time and labor costs, enhancing overall efficiency.

- Flexibility: Modern sheeters and laminators can be easily adjusted to produce a variety of cracker types, allowing manufacturers to diversify their product lines and meet changing consumer demands.

Find out more about Reading Bakery Systems sheeters and laminators for cracker production lines by calling 610-693-5816 or contacting us online.