At Reading Bakery Systems, we offer complete commercial bakery equipment solutions that can boost efficiency in every facet of your operation. Optimizing your bakery's production involves selecting and utilizing the right equipment to enhance efficiency, consistency, and quality. Here are a few considerations to help speed the process.

Assessing Your Bakery's Needs

The first step in optimizing production is to conduct a thorough assessment of your bakery's current operations. Identify the types of products you offer, your production volume and any bottlenecks or inefficiencies in your process. This assessment will help determine the specific equipment you need to improve productivity and streamline operations.

Investing in High-Quality Equipment

Investing in high-quality, reliable equipment is crucial for optimizing production. Consider the following types of equipment based on your bakery's needs:

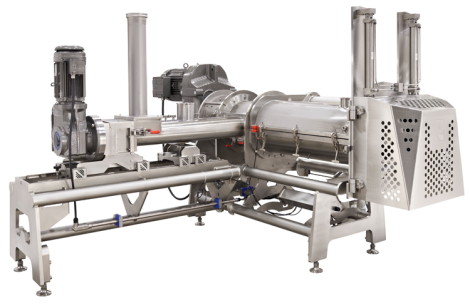

- Mixers: RBS makes industrial mixers that can handle large batches and offer consistent mixing. Planetary mixers are versatile and ideal for a variety of doughs and batters, while spiral mixers are great for bread dough.

- Ovens: Convection ovens ensure even baking and can handle multiple trays simultaneously. Deck ovens provide precise temperature control and are ideal for artisan breads and pastries.

- Proofers: A proofer cabinet helps control the fermentation process by maintaining optimal humidity and temperature, ensuring consistent results.

- Sheeters and laminators: For pastries and laminated doughs, sheeters and laminators streamline the process of rolling out dough to the desired thickness.

Implementing Best Practices for Equipment Use

Once you have the right equipment, it's important to implement best practices to maximize their efficiency:

- Regular maintenance: Schedule regular maintenance to keep your equipment in optimal condition. This includes cleaning, lubricating moving parts, and checking for wear and tear.

- Training staff: Ensure that all staff members are properly trained on how to use each piece of equipment. This reduces the risk of accidents and ensures efficient operation.

- Standard operating procedures (SOPs): Develop SOPs for each piece of equipment to ensure consistent use. SOPs should include step-by-step instructions for operating the equipment, as well as troubleshooting tips.

- Monitoring performance: Regularly monitor the performance of your equipment to identify any issues early. This can involve keeping logs of production times, output quality, and any maintenance performed.

Optimizing Workflow and Layout

The layout of your bakery can significantly impact production efficiency. Arrange your equipment in a logical sequence that minimizes movement and reduces the risk of cross-contamination. Consider the following tips:

- Workstations: Designate specific workstations for different stages of production, such as mixing, proofing, baking, and cooling.

- Flow of materials: Ensure a smooth flow of materials from one stage to the next. For example, place mixers near storage areas for ingredients, and position ovens close to the proofers.

- Space utilization: Make efficient use of space by using mobile racks and carts to transport products between workstations. This helps keep the workspace organized and reduces clutter.

Leveraging Technology

Incorporating technology into your bakery can further optimize production. Consider the following advancements:

- Automation: Automated systems, such as conveyors and robotic arms, can streamline repetitive tasks and reduce labor costs.

- Data analytics: Use data analytics to track production metrics, identify trends, and make informed decisions. Software solutions can help manage inventory, track sales, and optimize production schedules.

- Quality control: Implement quality control systems to ensure consistent product quality. This can involve automated inspection systems that check for defects and ensure uniformity.

Find Out More About How We Can Help

Optimizing your bakery's production with complete commercial bakery equipment solutions from Reading Bakery Systems involves a comprehensive approach. Taking these steps will help you enhance efficiency, improve product quality and, ultimately, increase profitability. Learn more by contacting us online or calling 610-693-5816.