Reading Bakery Systems is a global leader in industrial bakery technology. We can handle all aspects of your cracker manufacturing process and provide you with greater flexibility than ever before.

Reading Bakery Systems (RBS), headquartered in Robesonia, Pennsylvania, has been at the forefront of commercial baking systems and technology for more than 125 years. We serve customers in the global food service industries, providing state-of-the-art systems for the production of crackers, biscuits, pretzels, cookies, baked potato chips, bread snacks, baked crisps, pet treats and more.

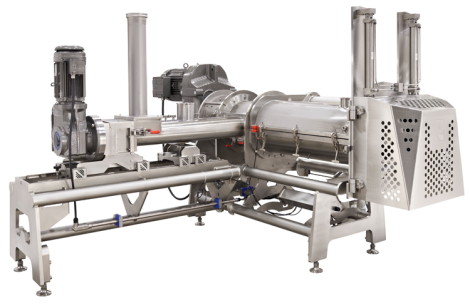

Continuous Mixing Solutions

Batch mixing is imprecise and often leads to dough variations that affect the consistency of your finished products. Reading Bakery Systems has now developed continuous mixing for the snack cracker industry, which offers several advantages:

- No undesirable variations from batch to batch

- Consistent finished weight, size and texture

- Even dough hydration

- Recipe control and repeatability

- High production rates with one mixer

- Completely automated process

- Eliminates chance of contamination

- Can be operated with less labor and energy than batch mixing

The Exact EX Continuous Mixer uniformly mixes products with a variety of dough moisture levels, reduces lay time, eliminates dough troughs, and reduces labor and energy thanks to full automation.This mixer offers dough production rates from 100 to 10,000 kg/hour.

Dough Forming Solutions

Thomas L. Green 3-roll, or 4-Roll Sheeters will enable you to create straight sheeted, dual sheeted and laminated crackers. The equipment will produce a hole-free sheet at a uniform density, critical to automated packaging systems after the oven. Consistent sheet thickness is controlled by the distance between the rolls that compress the dough (which is adjustable).

Our Thomas L. Green Servo-Cut Sheet Laminator accurately cuts, stacks and delivers sheets of dough for unique product textures. The precise and gentle placement of cut sheets provides uniform dough density at both the edges and center of the finished cracker sheet for consistency.

Baking Solutions

For more than 120 years, the Thomas L. Green PRISM OVEN, a flexible single-pass baking platform, has helped customers improve consistency with uniform color, taste, texture and quality.

The oven offers Direct Gas Fired (DGF), Emithermic (Radiant / Convection) and Convection zones. Each zone is available with a number of options to permit the precise combination of radiation, convection heating and conduction, providing the quality conscious baker with repeatable control of time, temperature, humidity and the type of heat transfer.

Conduct Confidential Trials

To explore the capabilities of our equipment, visit the Reading Bakery Systems Science & Innovation Center, a fully equipped, licensed research and development facility that offers a complete process line where customers can duplicate conditions they might encounter in full-scale production.

We encourage you to get in touch with Reading Bakery Systems at (01) 610-693-5816 to learn more about our extensive line of industrial equipment for your cracker manufacturing process, or click here to contact us online.