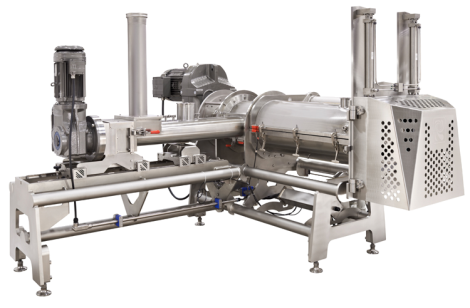

When it comes to producing high-quality baked goods, consistency is king. Whether you’re making bread, cookies, or pastries, maintaining a uniform product that meets consumer expectations every time is crucial to your bakery’s success. This is where dough handling and feeding equipment for commercial bakeries from Reading Bakery Systems plays a pivotal role. From mixing to portioning and proofing, using our equipment can make all the difference in achieving the consistent quality your customers expect.

Consistency Starts with Dough Handling

The first step in ensuring consistent product quality begins with how the dough is handled. Manual dough handling can lead to inconsistencies in texture, weight and shape, all of which affect the final product. Dough handling equipment automates these critical processes, ensuring that the dough is treated uniformly from start to finish.

For example, automated mixers ensure that ingredients are combined evenly, resulting in dough that has the same consistency every time. Automated dough dividers and portioning systems take this a step further by ensuring that each piece of dough is the exact same weight and size, which is essential for even baking. By automating these processes, you reduce the likelihood of human error, which can lead to uneven baking, overproofing or undercooking.

Improving Dough Consistency

One of the primary benefits of using advanced dough handling equipment is that it ensures consistent dough texture and quality. When you rely on manual methods, there’s always a risk of variability in how the dough is mixed, kneaded, and handled. This variability can lead to products that are too dense, too light, or improperly shaped.

With automated dough handling systems, you can control every aspect of the process, from ingredient ratios to mixing times. These machines are designed to handle dough with precision, ensuring that each batch has the same texture and elasticity. This is especially important for baked goods that require specific dough characteristics, such as bread, where the dough needs to develop the right amount of gluten for proper rise and texture.

By maintaining precise control over dough consistency, you’ll produce baked goods that not only look uniform but also have the same taste and texture across every batch.

Enhancing Efficiency and Reducing Waste

Dough handling equipment also contributes to overall production efficiency. By automating key stages of dough processing, you can significantly reduce the amount of time and labor needed to produce your products. Automated systems can portion dough more quickly and accurately than manual methods, which helps streamline production and reduce downtime.

In addition, advanced dough handling systems help reduce waste. For example, dough sheeters and portioners ensure that every piece of dough is cut to the exact specifications needed for each product. This level of precision reduces the likelihood of excess dough being trimmed or discarded, which can add up to significant savings over time. When you minimize waste, you not only improve your bottom line but also contribute to more sustainable production practices.

Ensuring Even Proofing and Baking

Dough handling equipment doesn’t just impact the initial stages of production; it also plays a critical role in ensuring that dough is properly proofed and baked. Automated proofing systems control temperature and humidity levels with precision, allowing dough to rise consistently across every batch. This ensures that your final products have the desired texture, shape and volume.

Please call 1 610-693-5816 or contact us online to learn more about dough handling and feeding equipment for commercial bakeries from Reading Bakery Systems.