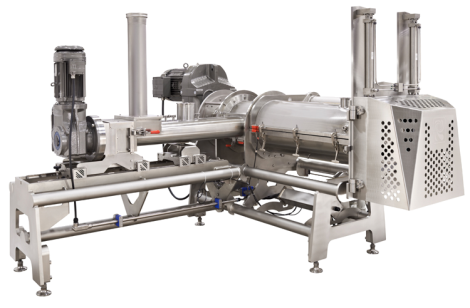

Reading Bakery Systems high-capacity rotary moulding equipment for industrial bakeries is perfect for high-volume production operations – especially those where consistency and efficiency are crucial. However, beyond its traditional use, our rotary moulding equipment can also play a significant role in product innovation, allowing bakeries to experiment with new shapes, textures, and formulations.

Enabling Unique Product Designs

One of the most significant contributions of rotary moulding to product innovation is its ability to create unique and intricate designs. The engraved cavities on the rotary moulding cylinder can be customized to produce a wide variety of shapes and patterns. This capability allows bakeries to differentiate their products from competitors by offering visually appealing baked goods that stand out on store shelves. Whether it’s seasonal shapes for holidays or custom designs for special occasions, rotary moulding provides the flexibility to innovate with product appearance.

Consistency and Precision in Production

Consistency is key in bakery production, especially when introducing new products. Rotary moulding machines are designed to produce uniformly shaped and sized baked goods with each production cycle. This level of precision ensures that every piece meets the same quality standards, which is essential when scaling up new product lines. The ability to consistently reproduce innovative designs across large batches not only enhances product appeal but also builds consumer trust in the brand.

Experimenting with New Dough Formulations

Rotary moulding isn’t just about shaping dough; it also opens up possibilities for experimenting with new dough formulations. Bakers can test different ingredient combinations, textures, and flavors while ensuring that the dough is still compatible with the rotary moulding process. This experimentation can lead to the development of innovative products that cater to changing consumer preferences, such as gluten-free or high-protein baked goods. The versatility of rotary moulding allows bakeries to push the boundaries of traditional baking and explore new market opportunities.

Speeding Up the Product Development Cycle

In the competitive bakery industry, the ability to bring new products to market quickly is a significant advantage. Rotary moulding machines are designed for high-speed production, allowing bakeries to rapidly prototype and test new product ideas. This speed is particularly beneficial during the initial stages of product development, where multiple iterations may be necessary to perfect the final product. By accelerating the development cycle, rotary moulding helps bakeries stay ahead of trends and respond swiftly to consumer demands.

Supporting Customization and Personalization

Customization and personalization are growing trends in the food industry, and rotary moulding offers a practical solution for bakeries looking to capitalize on these trends. With the ability to create custom moulds, bakeries can produce personalized baked goods for special events, corporate clients, or niche markets. This level of customization can be a powerful tool for building customer loyalty and creating unique product offerings that resonate with specific consumer segments.

Enhancing Product Texture and Mouthfeel

The rotary moulding process also has a direct impact on the texture and mouthfeel of baked goods. The pressure applied by the moulding cylinder can influence the density and structure of the final product, allowing bakers to create a range of textures from light and airy to dense and chewy. This control over texture is particularly important in product innovation, where the sensory experience plays a crucial role in consumer acceptance. By experimenting with different moulding techniques, bakeries can develop products that offer unique eating experiences.

Learn more about how high-capacity rotary moulding equipment for industrial bakeries from Reading Bakery Systems can boost your product innovation by contacting us online or calling 1 610-693-5816.