Reading Bakery Systems (RBS) manufactures industrial bakery equipment and complete turnkey systems that can help snack food production customers in Georgia and around the globe improve their products, streamline their processes, and maximize profitability.

Reading Bakery Systems provides high-quality systems for the production of crackers, biscuits, baked potato chips, cookies, pretzels, bread snacks, baked crisps, pet treats and more. No matter which type of snack foods you produce, we are ready to help you meet your process and product challenges.

Dough Mixing Solutions

Depending on your level of automation, RBS offers batch and continuous mixing systems. Continuous mixing offers customers numerous advantages over batch mixing. The biggest advantage in all applications is the ability to produce large quantities of uniform dough and, therefore, a more consistent finished product.

Exact Mixing offers several mixer models that are appropriate for different types of products with production volumes that range from 50 kg/hour to over 10,000 kg/hour.

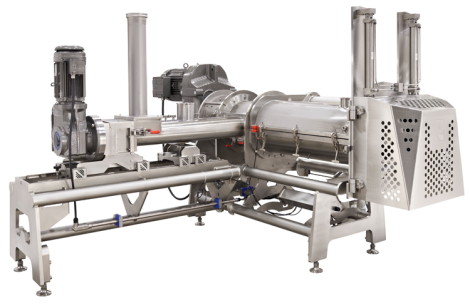

One model, the Exact EX Continuous Mixer, is ideal for crackers, pretzels, pie crusts, pet treats and a variety of other wheat-based snacks. Its mixing shaft can be configured with interchangeable mixing elements to mix a wide variety of dough and offers dough production rates from 100 to 10,000 kg/hour.

Another, the Exact HDX Continuous Mixer, is a two-stage system that is ideal for manufacturing highly developed dough at low temperatures. It provides precise and uninterrupted ingredient delivery to the mixer and offers dough production rates from 1,500 to 10,000 kg/hour.

Baking & Drying Solutions

The Thomas L. Green PRISM OVEN is a powerful system for uniform baking of products such as hard and soft biscuits, cookies, crackers, English muffins and snack cakes. It employs Direct Gas Fired (DGF) Zones, Emithermic (Radiant / Convection) Zones and Convection Zones, each with a number of options to provide your baked products with uniform quality, color, taste and texture. Customers appreciate this oven’s capacity for repeatable control of time, temperature, humidity and type of heat transfer.

The Reading Pretzel SPECTRUM OVEN® offers radiation, convection and conduction heat transfer options in a single modular design, making it ideally suited to extruded pretzels and snacks, baked snack crisps and pet treats. The SPECTRUM OVEN® features an easy-to-use system that gives the operator complete control of oven temperature, humidity, and product bake time. The addition of an optional Multi-Pass Dryer will increase oven speed, production throughput and process control.

Turnkey Production Systems

RBS also manufactures and installs turnkey production systems with the latest technology to efficiently and profitably produce baked snacks. For example, consider our Pretzel & Snack Systems, Cracker Systems, Hard & Soft Biscuit Systems, Pet Treat Systems, and our other modern, high volume systems.

As suppliers of innovative industrial bakery equipment, Reading Bakery Systems would be happy to tailor a solution for your bakery in Georgia that meets your needs. Contact us in Robesonia, Pennsylvania at (01) 610-693-5816, or click here to find out more about our products.