Reading Bakery Systems helps customers in Israel and around the world perfect their processes and their products with industrial baking equipment and complete turnkey systems that are specifically tailored to their needs.

Reading Bakery Systems (RBS), headquartered in Robesonia, Pennsylvania, USA, can help you solve your production challenges with innovative thinking and technologically advanced systems and components. Our equipment line includes cost-effective mixing, dough handling, forming, baking, and drying solutions for every part of your process.

Turnkey Production Systems

RBS manufactures and installs complete turnkey production systems that feature the latest technology and can help customers efficiently and profitably produce baked snacks.

The modern, high volume Cracker System, for example, enables you to create straight sheeted, dual sheeted and laminated crackers. Sheeting systems can range from 600mm to 1.5m in width, and production volumes range from 200-5500 kg/hr depending on oven length, width and product type.

The Multi-Crisp Baked Snack System enables you to produce a variety of wheat, potato, multi-grain and corn masa flour crisps on one flexible system. The system can produce between 250-1000 kg/hr of finished product, depending on the number of oven sections after the dough sheeting equipment.

Continuous Mixing Solutions

Batch mixing can affect the consistency of your finished products by causing dough variations.Continuous mixing has grown in popularity around the world for its ability to continuously produce a more consistent dough.

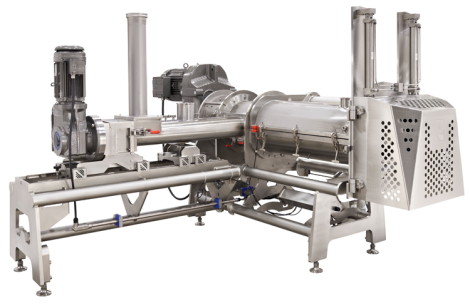

Our Exact Continuous Mixers come in a variety of sizes that range from 50 to 10,000 kg/hour. Different models are available based primarily on dough moisture levels and number of mixing stages.

They include the Exact MX Continuous Mixer, our most versatile mixer, which is well suited for a wide range of products including pizza, cookies, snacks, batters, icings, and pastes, the Exact EX Continuous Mixer, which is ideal for crackers, pretzels, sweet goods, pet treats and other wheat-based products, and the Exact HDX or High Development Continuous Mixer, which is designed for ultra-high absorption doughs, such as buns, breads, rolls and English muffins.

Innovative Oven Technology

The biscuit, cookie and cracker industry has trusted Thomas L. Green ovens for more than 120 years. The PRISM OVEN is designed to enhance product consistency. Features include:

- Direct gas fired (DGF), convection, and Emithermic (radiant / convection) baking zones

- Better baking efficiency with uniform quality, color, taste and texture

- Repeatable control of time, temperature, humidity and type of heat transfer

When your product line involves pretzels, bread snacks, potato chips and other crisp baked snacks, the flexible Reading Pretzel SPECTRUM OVEN® offers the same flexibility as the PRISM OVEN and features:

- Radiation, convection and conduction heat transfer options

- Repeatable control of time, temperature, humidity and type of heat transfer

- Separate heating zones for more precise control

- Stainless steel interior construction

A separate optional Multi-Pass Dryer provides faster oven speeds, greater production throughput, and more process control. The Dryer efficiently reduces product core moistures, improving overall quality and storage characteristics.

When you are seeking industrial bakery equipment for your bakery in Israel, learn how Reading Bakery Systems can meet your needs by contacting RBS Sales Representative, John Eshelman, at (01) 610-693-5816, or click here to contact us online.