Reading Bakery Systems offers state-of-the-art industrial bakery equipment to customers in London and throughout the United Kingdom, and is focused on innovation, reliability, and legendary worldwide service and customer support.

Reading Bakery Systems, headquartered in Robesonia, Pennsylvania, USA, offers high-quality solutions to customers in the global food and snack industries, providing reliable and efficient systems for the production of cookies, crackers, biscuits, pretzels, baked potato chips, bread snacks, baked crisps, pet treats and more.

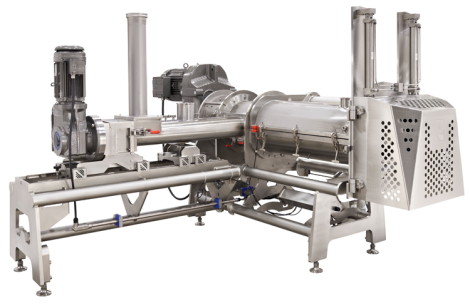

Mixing Technology

The Thomas L. Green Vertical Spindle Mixer is suitable for biscuit, cookie and cracker products, and doughs that require a two-stage mixing process with a fermentation period in between. The mixer allows the same dough to be mixed twice and stay in the same trough throughout the process.

Customers can simplify their mixing process and eliminate the undesirable dough variations caused by batch mixing with Exact Mixing Continuous Mixing technology from Reading Bakery Systems.

The Exact Mixing MX Continuous Mixer is our most versatile mixer and is well suited for a wide range of products including pizza, cookies, snacks, batters, icings, and pastes. It is also an ideal first stage mixer for processes that require creme up and pre-blend stages.

The Exact Mixing HDX Continuous Mixer, is an excellent choice for ultra-high absorption doughs, such as buns, breads, rolls, English muffins and similar products.

If you manufacture pretzels, crackers, pet treats or other wheat-based products, the Exact Mixing EX Continuous Mixer uniformly mixes products with a variety of dough moisture levels and is well-suited to all but the lowest viscosity powder/liquid mixtures.

Dough Forming Technology

The Reading Pretzel Low Pressure Extruder offers exceptional flexibility, enabling you to create a variety of pretzel shapes, sticks, braids, filled sticks and bread snacks on one production line. Product changeover is as simple as exchanging one compression head and die for another one with a different shape.

For rotary moulded snacks, the Thomas L. Green Rotary Moulder efficiently produces high definition, 3-D shapes by pressing dough into a die roll. The interchangeable engraved brass die roll can be supplied with segmented rings for simultaneous, multi-shape production.

The Thomas L. Green Sheeter generates a consistent dough sheet, and Gauging Stations ensure a gentle reduction in sheet thickness prior to shape forming. Scrapless geometric shapes and distinct shapes can be formed by the Rotary Cutting Station.

Baking & Drying Technology

When you manufacture biscuits, cookies or crackers, the Thomas L. Green PRISM OVEN is an excellent choice. The single-pass baking platformoffers direct gas fired (DGF), convection, and Emithermic (radiant / convection) baking zones and is designed to improve consistency and promote uniform product quality, color, taste and texture.

Customers who manufacture pretzels, bread snacks, crisps, and potato snacks will benefit from the variety of heat transfer options (radiation, convection and conduction) in the modular Reading Pretzel SPECTRUM OVEN®.

The baking platform features operator-controlled air temperature, circulation speed, exhaust, and moisture removal for reliable, consistent baking. Add a separate optional SPECTRUM Multi-Pass Dryer to increase oven speed, production throughput and process control.

As suppliers of innovative industrial bakery equipment, Reading Bakery Systems can customize a solution for your London bakery that meets your needs. Contact our European Sales Manager, Joe Pocevicius, at +31-615-510-789, call our headquarters at (01) 610-693-5816, or click here to learn more about our equipment.