From innovative continuous mixers to the most advanced oven systems, the world’s finest industrial equipment from Reading Bakery Systems can improve the processes in your commercial bakery in Missouri and help you meet increasing demand for your snack products.

Reading Bakery Systems (RBS), headquartered in Robesonia, Pennsylvania, has been at the forefront of commercial baking systems and technology for more than 120 years.

We serve customers in the global food service industries, providing superior systems for the production of biscuits, crackers, pretzels, cookies, sweet goods, baked potato chips, bread snacks, baked crisps, pet treats and more.

About Continuous Mixing

Batch mixing has been the primary mixing method in the bakery industry for many years. However, newer technologies developed over the last 20 years have made it possible to produce as much as 20,000 pounds of dough per hour on an as-needed basis with the help of modern bulk handling and metering technologies.

The advantages of continuous mixing include:

- More precise delivery of raw materials to the mixer

- Improved consistency of weight, size and texture

- Elimination of dough troughs

- Recipe control and repeatability

- Completely automated process

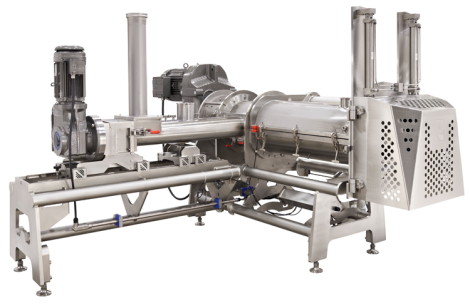

Exact Continuous Mixers come in a variety of sizes, ranging from 50 to 10,000 kg/hour. Models include the Exact MX Continuous Mixer, our most versatile mixer, which can be used for a wide range of products including cookies, snacks, pizza, batters, icings, and pastes.

The Exact EX Continuous Mixer is ideal for crackers, pretzels, sweet goods, pet treats and other wheat-based products, and the Exact HDX Continuous Mixer is well-suited to products such as buns, breads, English muffins and similar products, and is designed to manufacture highly developed dough at low temperatures.

Baking & Drying Equipment

Customers in the global biscuit, cookie and cracker industry have trusted the Thomas L. Green PRISM OVEN for more than a century. The single-pass baking platform is designed to improve consistency and promote uniform product quality, color, taste and texture.

The Reading Pretzel SPECTRUM OVEN® offers the same flexibility as the PRISM OVEN for baking pretzels, bread snacks, crisps and potato snacks, with a number of different combinations of heat transfer zones in one modular design.

The addition of an optional SPECTRUM Multi-Pass Dryer increases oven speed, production throughput and process control.

Turnkey Systems

RBS also manufactures and installs turnkey production systems with the latest technology to efficiently and profitably produce baked snacks. Our systems create sheeted and rotary moulded products and have the flexibility to integrate batch or continuous mixing.

The modern, high volume Cracker System, for example, enables you to create straight sheeted, dual sheeted and laminated crackers. Sheeting systems can range from 600mm to 1.5m in width, and production volumes range from 200-5500 kg/hr depending on oven length, width and product type.

The Multi-Crisp Baked Snack System enables you to produce a variety of wheat, potato, multi-grain and corn masa flour crisps on one flexible system. The system can produce between 250-1000 kg/hr of finished product, depending on the number of oven sections after the dough sheeting equipment.

When you need industrial equipment for your Missouri bakery, we encourage you to get in touch with Reading Bakery Systems by clicking here or calling (01) 610-693-5816 to discover how we can meet your needs.