As a global leader in the snack food industry, Reading Bakery Systems (RBS) manufactures technologically advanced industrial bakery equipment for customers in Poland and around the world, including innovative continuous mixing equipment and the most advanced commercial oven systems.

Improve your products, streamline your processes and maximize your bakery’s profitability with RBS’ industry-leading brands – Thomas L. Green, Reading Pretzel, Reading Thermal and Exact Mixing. No matter which snack foods you produce, we are ready to help you meet your challenges.

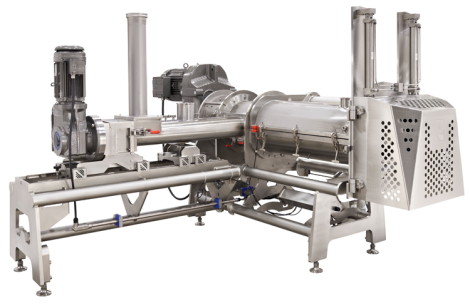

Continuous Mixing

Consider our continuous mixing technology when you are interested in producing a more consistent dough and finished product. Our Exact Continuous Mixers come in many sizes, ranging from 50 to 10,000 kg/hour, and include the Exact MX Continuous Mixer, our most versatile mixer, can be used for a wide range of products including cookies, snacks, batters, icings, and pastes, and the Exact EX Continuous Mixer, which is ideal for crackers, pretzels, pizza, sweet goods, pet treats and other wheat-based products.

Dough Forming

For extruded and co-extruded snacks, the Reading Pretzel Low Pressure (LP) Extruder enables bakeries to create a variety of structural, flat and filled extruded and co-extruded shapes and sticks. It is a more flexible, cost-effective alternative to conventional dough forming and sheeting systems for customers who produce a variety of snack products.

For rotary moulded snacks, the Thomas L. Green Rotary Moulder efficiently produces high definition, three dimensional shapes by pressing dough into a die roll. The interchangeable engraved brass die roll can be supplied with segmented rings for simultaneous, multiple shape production.

For sheeted snacks, the Thomas L. Green Sheeter generates a consistent dough sheet, and Gauging Stations ensure a gentle reduction in sheet thickness prior to shape forming. Scrapless geometric shapes and distinct shapes can be formed by the Rotary Cutting Station.

Oven Technology

The Thomas L. Green PRISM OVEN is a powerful system for uniform baking of products such as hard and soft biscuits, cookies, crackers, English muffins and snack cakes. It employs Direct Gas Fired (DGF) Zones, Emithermic (Radiant / Convection) Zones and Convection Zones, each with a number of options to provide your baked products with uniform quality, color, taste and texture. Customers appreciate this oven’s capacity for repeatable control of time, temperature, humidity and type of heat transfer.

The Reading Pretzel SPECTRUM OVEN® offers radiation, convection and conduction heat transfer options in a single modular design, making it ideally suited to extruded pretzels and snacks, baked snack crisps and pet treats. The SPECTRUM OVEN® features an easy-to-use system that gives the operator complete control of oven temperature, humidity, and product bake time.

When you need industrial bakery equipment in Poland, learn more about our complete product line by contacting our European Sales Manager, Joe Pocevicius, at +31-615-510-789, our U.S. headquarters at (01) 610-693-5816, or click here to connect with us online.