Reading Bakery Systems is a leader in the baked snack food industry, providing high-quality industrial bakery equipment for customers in Portugal and worldwide.

Headquartered in Robesonia, Pennsylvania, USA, Reading Bakery Systems (RBS) designs, engineers and manufactures the world’s most innovative equipment for the production of crackers, biscuits, baked potato chips, cookies, pretzels, bread snacks, baked crisps, pet treats and more, and can help you meet your process and product challenges.

Our service and technical support teams travel to sites around the world to guide you through the installation of new processing lines and train plant personnel on maintenance and safety issues. We understand how on-site training, a quick response time, and outstanding support services can make the difference between simply making snack foods and making the best snack foods in the industry.

Continuous Mixing Solutions

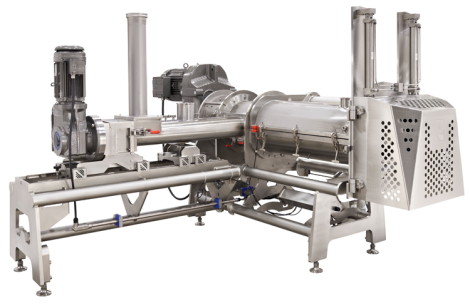

Continuous mixing has grown in popularity around the world for its ability to continuously produce a more consistent dough.

Our Exact Continuous Mixers come in a variety of sizes that range from 50 to 10,000 kg/hour. Different models are available based primarily on dough moisture levels and number of mixing stages.

They include the Exact MX Continuous Mixer, our most versatile mixer, which is well suited for a wide range of products including pizza, cookies, snacks, batters, icings, and pastes, the Exact EX Continuous Mixer, which is ideal for crackers, pretzels, sweet goods, pet treats and other wheat-based products, and the Exact HDX or High Development Continuous Mixer, which is designed for ultra-high absorption doughs, such as buns, breads, rolls and English muffins.

Dough Forming Solutions

When you need exceptional extrusion machinery that offers high quality and precision, the solutions from RBS are designed and engineered to meet your production needs.

The Reading Pretzel Low Pressure (LP) Extruder enables you to create a variety of structural and flat extruded and co-extruded shapes and sticks on one production line. It is a flexible alternative to conventional dough forming and sheeting systems.

The Reading Pretzel Filled Stick Extrusion System creates sticks filled with soft fillings, such as cheese, chocolate, and peanut butter. The product rope that is produced is cut into equal length sticks or nuggets by a downstream Guillotine Cutter.

Baking & Drying Solutions

The Thomas L. Green PRISM OVEN is a flexible single-pass baking platform that offers Direct Gas Fired (DGF) zones, Emithermic (Radiant / Convection) zones and Convection zones for cookies, crackers and biscuits to provide balanced and consistent quality, color, taste and texture.

The Reading Pretzel SPECTRUM OVEN® offers radiation, convection and conduction heat transfer options in a single modular design and is the ideal oven for baked potato chips, baked crisps, extruded pretzels, bread snacks and pet treats. The convection baking platform features operator-controlled air temperature, circulation speed, exhaust, and moisture removal for reliable, consistent baking of snacks.

As suppliers of innovative industrial bakery equipment, Reading Bakery Systems can customize a solution for your bakery in Portugal. Contact our European Sales Manager, Joe Pocevicius, at +31-615-510-789, call our U.S. headquarters at (01) 610-693-5816, or click here to explore our wide range of equipment.