As leading manufacturers of the world’s most advanced industrial cracker manufacturing equipment and a complete range of other commercial baking equipment, Reading Bakery Systems can help you reduce costs and produce consistent, high-quality products.

Reading Bakery Systems, headquartered in Robesonia, PA, serves snack food manufacturers around the globe. We offer a complete line of mixing, dough handling and forming, baking, drying, and supplemental equipment that helps customers meet their challenges when processing fermented or unfermented cracker dough, biscuit dough and other two-stage or proofed-dough products.

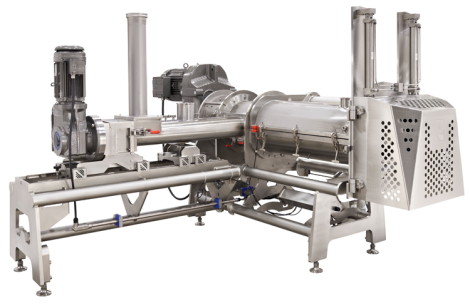

Mixing Equipment

Batch mixing is imprecise and often leads to dough variations that affect the consistency of your finished products. Reading Bakery Systems has now developed continuous mixing for the snack cracker industry, which offers several advantages:

- No undesirable variations from batch to batch

- Consistent finished weight, size and texture

- Even dough hydration

- Recipe control and repeatability

- High production rates with one mixer

- Completely automated process

- Eliminates chance of contamination

- Can be operated with less labor and energy than batch mixing

The Exact EX Continuous Mixer uniformly mixes products with a variety of dough moisture levels, reduces lay time, eliminates dough troughs, and reduces labor and energy thanks to full automation.This mixer offers dough production rates from 50 to 10,000 kg/hour.

Sheeting & Laminating Equipment

The 2-roll, 3-roll, or 4-Roll Sheeter will produce a hole-free sheet at a uniform density, critical to automated packaging systems after the oven. The thickness of the sheet produced is controlled by the distance between the rolls (which is adjustable). The rolls compress the dough into a single sheet with consistent characteristics and thickness.

Our Thomas L. Green Servo-Cut Sheet Laminator and In-Line Laminator accurately cut, stack and deliver sheets of dough for unique product textures. The precise and gentle placement of cut sheets provides uniform dough density at both the edges and center of the finished cracker sheet for consistency. Dough sheeters may be installed to the side, or directly above, the Laminator for a compact and efficient production layout.

Baking Equipment

Thomas L. Green ovens have been trusted by the global cracker industry for more than 120 years. The PRISM OVEN is a flexible single-pass baking platform designed to enhance product consistency. The oven offers Direct Gas Fired (DGF), Convection and Emithermic (radiant/convection) zones for balanced and consistent quality, color, taste and texture of crackers, cookies and biscuits.

Make the most of both zones with product development and “cooking” in the Emithermic zone and efficient moisture removal and coloring in the convection zone. Customers appreciate the PRISM oven’s capacity for repeatable control of time, temperature, humidity and type of heat transfer.

Conduct Confidential Trials

To explore the capabilities of our equipment, visit the Reading Bakery Systems Science & Innovation Center, a fully equipped, licensed research and development facility that offers a complete process line where customers can duplicate conditions they might encounter in full-scale production.

Call Reading Bakery Systems at (01) 610-693-5816 to learn more about our extensive range of industrial cracker manufacturing equipment, or click here to contact us online.