The Thomas L. Green brand of industrial dough laminators from Reading Bakery Systems are designed to treat dough as gently as possible to help customers create higher quality products.

As a long-time global leader in the snack food industry, Reading Bakery Systems (RBS) has been at the forefront of commercial baking systems and technology for more than a century. Our Thomas L. Green brand has been supplying efficient, reliable and cost-effective commercial baking equipment since 1893.

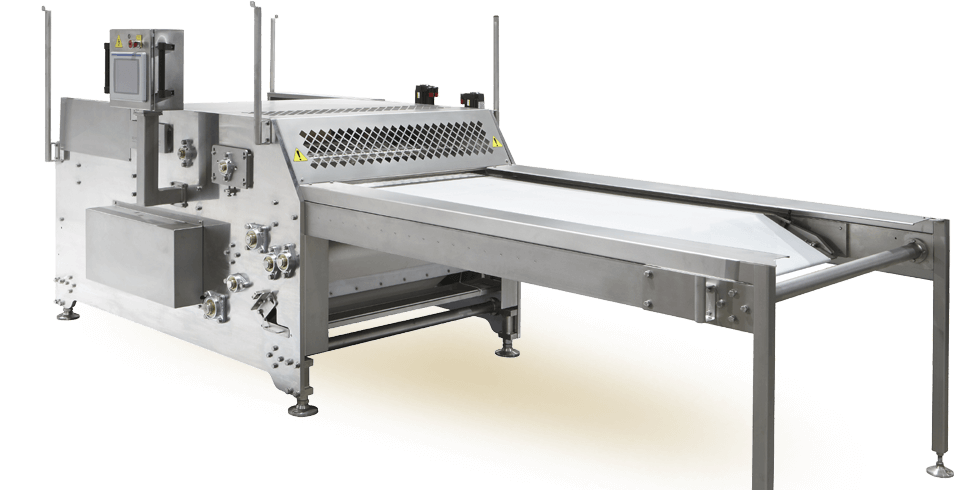

Dough Lamination

Lamination is the process of layering the dough sheet to create a flaky texture. Uniformity of the layers assist in bakers’ efforts to make high quality baked foods.

Our Thomas L. Green laminators utilize precision servo motor control to accurately cut, stack and deliver sheeted dough to downstream reduction and forming equipment.

90° Servo Cut Sheet Laminator and Servo In-Line Laminator: Dough sheets are conveyed to the discharge conveyor by the servo driven layering carriage. This carriage deposits the sheets by extending them to the far edge of the laminator take-away conveyor. The carriage retracts while conveying, laying the sheets gently on top of the moving lamination stack.

Features:

- Precise, automatic, and synchronized computer control of dough sheet length, conveyor speed, and number of laminations

- Sheet placement is indexed from the touchscreen control interface

- The rotary knife cut depth is adjustable as the knife passes through the dough sheet, ensuring a clean separation of individual sheets

- A dough sheeter may be installed to the side or directly above the laminator for a compact and efficient production layout

- Numerous configurations are available depending on product type and available plant space

- SafeShield Program standards that ensure operator safety, easy and quick sanitation, and food safety

Downstream Equipment

The Thomas L. Green Gauging Station is a fundamental machine in most cracker, biscuit, pizza or chip production lines. Parallel, hardened rolls typically reduce the dough sheet thickness by a 3:1 ratio from infeed to discharge. The gap between the rolls can be monitored by the control system and automatically adjusted to maintain constant dough thickness.

The Thomas L. Green Rotary Cutting Station accurately and continuously cuts distinct product shapes out of a single dough sheet. An integrated conveyor system moves product through - and is pressured against - a rotating die assembly. Operators can adjust the pressure on the dough sheet during operation to ensure a thorough cut and consistent piece production.

The Thomas L. Green PRISM OVEN is a flexible single-pass baking platform designed to enhance product consistency. The oven offers Emithermic, Direct Gas Fired (DGF) and Convection zones for balanced and consistent quality, color, taste and texture of crackers, cookies and biscuits.

Make the most of both zones with product development and “cooking” in the Emithermic zone and efficient moisture removal and coloring in the convection zone. Customers appreciate the oven’s capacity for repeatable control of time, temperature, humidity and type of heat transfer.

We encourage you to get in touch with Reading Bakery Systems at (01) 610-693-5816 to explore our extensive line of industrial dough laminators and other production equipment, or click here to contact us online.