Industrial dough sheeters create a consistent dough sheet that is critical to automated packaging systems after the oven. Reading Bakery Systems offers multiple sheeter options depending on the type of product you would like to produce.

Headquartered in Robesonia, Pennsylvania, Reading Bakery Systems (RBS) offers state-of-the-art solutions to customers in the global food and snack industries, providing reliable and efficient systems for the production of cookies, crackers, biscuits, pretzels, baked potato chips, bread snacks, baked crisps, pet treats and more.

Sheeting Innovations

Thomas L. Green has been a trusted partner to the biscuit, cracker and snack crisps industries for over 125 years, supplying innovative, reliable, and cost-effective sheeting equipment.

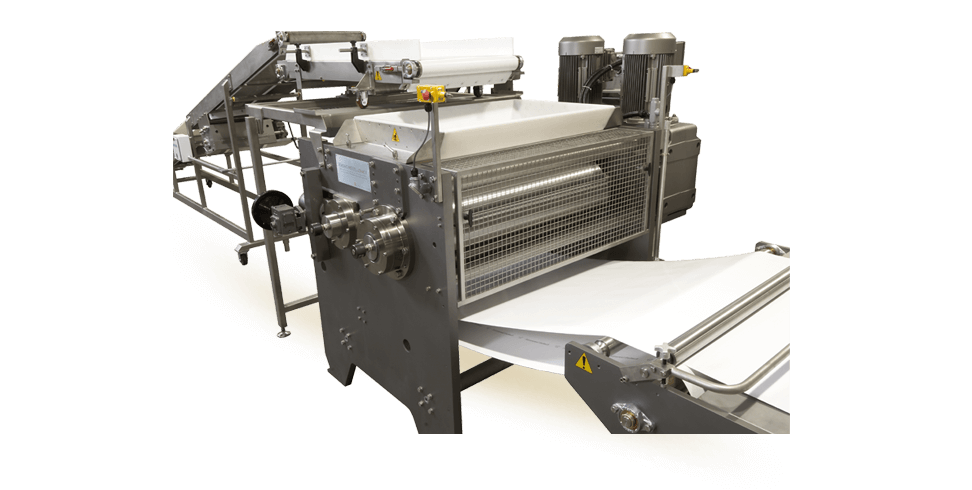

Our Thomas L. Green sheeters produce hole-free sheets of uniform density to ready the dough for forming, lamination or further reduction. Consistent sheet thickness is controlled by the distance between the rolls that compress the dough (which is adjustable).

The 2-Roll Sheeter features two powered stainless steel rolls that rotate toward one another and draw raw dough into a single sheet with consistent characteristics and thickness. The stainless steel rolls are manufactured to precise tolerances of concentricity in order to maintain consistent dough sheet formation.

The 3-Roll Sheeter features two forcing rolls that draw the dough into the pressurized cavity between the three rolls, and the dough is compacted and discharged as a continuous sheet.

The 4-Roll Sheeter features two upper forcing rolls that draw the dough into the pressurized cavity between the four rolls. The two lower rolls are smooth and maintain a constant density of dough, creating a smooth dough sheet.

The Fabricated Chip Sheeter is a forming machine capable of sheeting and cutting shapes from potato doughs that consist of dry premixes, potato flakes, whole grains, corn and other formulations. Dough is delivered to a hopper above two large-diameter, solid core, water-cooled sheeting rolls. In a single pass, dough is reduced and sheeted to a typical thickness of 0.7mm (.027”). Cut shapes are delivered directly into an oven or fryer prior to seasoning and packaging.

Test Your Products & Processes

If you are not sure which equipment may be right for your products, we encourage you to visit with our team at the RBS Science & Innovation Center in Sinking Spring, Pennsylvania, to determine which equipment may be right for your products.

Customers can work with our team to test machinery and processing techniques; research innovations in mixing, forming, baking and drying that can increase your profitability; develop new products; validate new ingredients and test ingredient changes; and produce market samples for testing.

When you need industrial dough sheeters or other commercial bakery equipment, we encourage you to contact Reading Bakery Systems by clicking here or calling (01) 610-693-5816 to discover how we can meet your needs.