When you need industrial wirecut dough forming equipment or other advanced bakery equipment for your cookie production line, consider Reading Bakery Systems.

Reading Bakery Systems (RBS), headquartered in Robesonia, Pennsylvania, designs, engineers and manufactures the world’s most innovative equipment for the production of cookies, crackers, biscuits, pretzels, baked potato chips, bread snacks, baked crisps, pet treats and more, and can help you reduce labor, cut costs, and produce consistent, high-quality products.

Wirecut Cookie Solutions

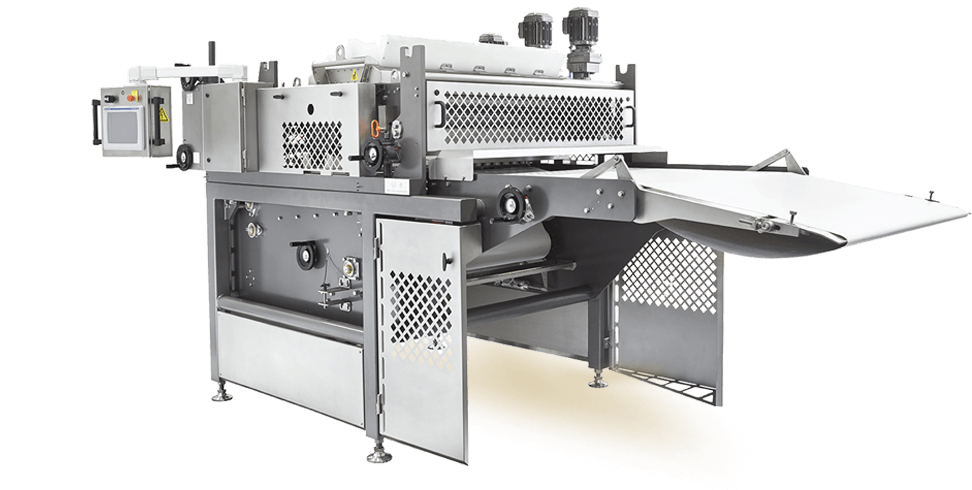

The Thomas L. Green Independence Wirecut Machine creates a variety of cookies and biscuits. It provides piece-weight accuracy and reliability, and is best for nondescript shapes, with or without inclusions.

The Wirecut Machine uniformly cuts individual shapes at up to 300 cuts per minute, depending on product type. Both digital and manual controls are included for optimal process control, and the cutting wire can be interchanged for products with different densities and inclusions.

This cutting-edge equipment optimizes output and efficiency to improve your products and your process. Product settings can be stored as a machine “recipe,” and hopper and wirecut head assemblies can be completely removed for sanitation and preventative maintenance.

The Wirecut Machine can be supplied as a mobile unit with an integrated transfer conveyor or it can be installed directly onto an existing production frame.

Explore Other Cookie Manufacturing Equipment

Mixing: Our continuous mixing equipment accurately delivers ingredients to the mixer at rates high enough to help you produce a better-quality finished product. The Exact MX Continuous Mixer is our most versatile mixer. It offers dough production rates from 50 to 2,000 kg/hour and is ideal for a wide range of products including cookies, snacks, pizza, batters, icings, and pastes.

Rotary Moulding: If your production involves high definition, three dimensional cookies, sandwich cookies, bars or biscuits, the Rotary Moulder features an interchangeable die roll made of engraved brass that can be supplied with segmented rings for multiple shapes.

Baking: The cookie industry has trusted Thomas L. Green ovens for more than 125 years. The PRISM OVEN is ideally suited for cookie production with a single-pass baking platform designed to enhance consistency and deliver uniform quality, color, taste and texture.

The PRISM OVEN offers Direct Gas Fired, Convection, and Emithermic (radiant/convection) baking zones. When your cookies demand consistency, capitalize on the technology by “cooking” in the direct gas fired zone and removing moisture and coloring in the convection zone.

To experience the capabilities of our mixing, forming and baking equipment, visit the RBS Science & Innovation Center in Sinking Spring, Pennsylvania. The fully equipped and licensed research and development facility offers a complete process line where customers can develop new products, validate new ingredients, test ingredient changes, and duplicate conditions they might encounter in full-scale production.

Reading Bakery Systems is a leading manufacturer of industrial wirecut machines and other dough forming equipment. Contact us today at (01) 610-693-5816 to find out how we can help perfect your process and your product.