The manufacturing process of extruded snacks involves pushing ingredients through a die under high pressure and temperature, resulting in a variety of snack forms. Advanced equipment from Reading Bakery Systems plays a crucial role in enhancing this process, improving efficiency, product quality, and consistency. Here are just a few of the ways.

Precision and Control

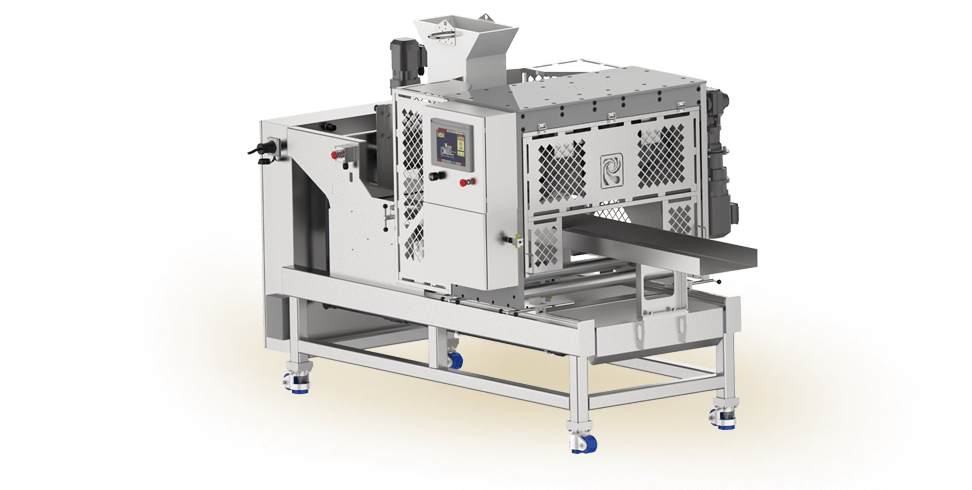

Advanced extrusion equipment from RBS offers unparalleled precision and control over the manufacturing process. Modern extruders are equipped with sophisticated control systems that allow manufacturers to precisely adjust parameters such as temperature, pressure and screw speed. This level of control ensures consistent product quality and enables the production of a wide range of snack types.

Versatility in Product Design

With advanced equipment, manufacturers can easily switch between different product designs. Multi-functional extruders can handle various dies and cutting systems, allowing for the production of snacks in different shapes and sizes. This versatility is essential for meeting consumer demands and staying competitive in the market.

Enhanced Automation

Automation is a key feature of modern extrusion equipment. Automated systems reduce the need for manual intervention, minimizing human error and increasing production efficiency. Automated feeders, mixers and cutters ensure that ingredients are consistently measured and processed, leading to uniform products. Automation also allows for continuous production, significantly increasing output.

Improved Mixing and Conditioning

RBS advanced extruders are designed to handle complex ingredient mixes, ensuring thorough blending and conditioning. The improved mixing capabilities ensure that all ingredients are evenly distributed, which is crucial for flavor consistency and texture. Conditioning systems pre-treat the ingredients to achieve the desired moisture content and temperature, optimizing the extrusion process.

Consistency in Product Quality

Consistency is a hallmark of successful snack production. Advanced extruders ensure that every batch of snacks meets the same high standards of quality. Precise control over processing parameters means that variations in texture, shape, and flavor are minimized. This consistency builds brand trust and consumer loyalty.

Energy Efficiency

Modern extrusion equipment is designed with energy efficiency in mind. Advanced heating and cooling systems, along with optimized motor designs, reduce energy consumption without compromising performance. Energy-efficient equipment lowers operational costs and aligns with sustainability goals, making the manufacturing process more eco-friendly.

Scalability

As demand for extruded snacks grows, the ability to scale production is critical. Advanced extrusion systems are designed to accommodate increased production volumes. Modular designs allow manufacturers to expand their production lines without significant disruptions. Scalability ensures that manufacturers can meet market demands efficiently.

Hygiene and Safety

Food safety and hygiene are paramount in snack manufacturing. Advanced extruders are constructed with materials that meet stringent hygiene standards. They are designed for easy cleaning and maintenance, reducing the risk of contamination. Automated systems also enhance safety by minimizing the need for manual handling of ingredients and finished products.

Contact Us to Learn More

Advanced equipment from RBS revolutionizes the manufacturing process of extruded snacks by enhancing precision, control and efficiency. The benefits of using modern extrusion technology include consistent product quality, energy efficiency, scalability, and improved hygiene and safety. Our innovations continue to push the boundaries of what is possible in snack production.

Investing in advanced equipment from Reading Bakery Systems helps manufacturers optimize their processes, meet consumer demands, and stay competitive in a rapidly evolving market. Learn more about our products by contacting us online or calling 610-693-5816.