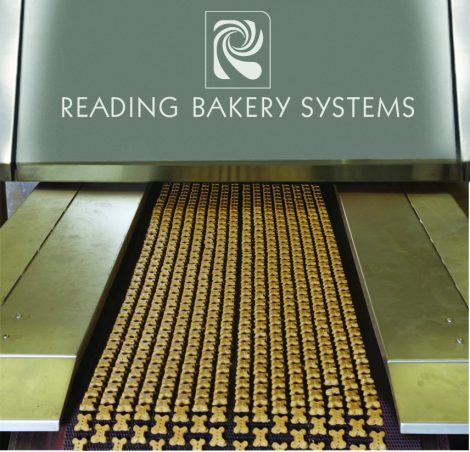

Whether your pet food processing equipment needs involve mixing, dough forming, baking, drying, or another efficient, cost-effective solution, Reading Bakery Systems delivers an unmatched level of commitment to high quality and customer support.

Reading Bakery Systems (RBS), headquartered in Robesonia, Pennsylvania, serves customers in the global snack food industry, providing high-quality equipment for the production of stackable potato chips, baked potato chips, baked crisps, and other products such as crackers, biscuits, pretzels, bread snacks, dry pet food, pet treats and more.

With more than 120 years of expertise and an unmatched range of equipment, customers rely on our technologically advanced mixing, forming and cutting equipment to improve efficiency, quality, volume and profitability.

If you are new to the pet treat industry or want to explore methods of improving your volumes or production processes, consider working with our team in the Reading Bakery Systems Science & Innovation Center.

The Center gives customers access to our unrivaled expertise in manufacturing, research and development, quality assurance, equipment design, production management, and process development, as well as assistance in die design and custom equipment development.

Mixing Solutions

Continuous Mixing eliminates the undesirable dough variations that are caused by batch mixing, improving process efficiency and product consistency.

The Exact EX Continuous Mixer, for example, is ideal for both soft, chewy and hard, crunchy dry pet food and pet treats. Dough delivery can be automated with a mini-laytime conveyor and chunker, kibbler or sheeter attachments.

Continuous mixing offers additional advantages over batch mixing, including:

- Completely automated process

- Easier handling of materials

- Recipe control and repeatability

- More consistent finished products

- Less floor space

- Less labor and energy

- For non-baked products, achieve verifiable kill temperatures

Dough Forming Solutions

For high-definition 3-D shapes, the Thomas L. Green Rotary Moulder presses dough into interchangeable die rolls and is available with segmented rings for simultaneous, multi-shape production.

The flexible Reading Pretzel Low Pressure (LP) Extruder enables you to produce a variety of structural, flat and filled extruded shapes and sticks on one production line. Quickly exchange compression heads and dies to change shapes and broaden your product range.

If you manufacture pet treats with soft fillings, another option to consider is the Reading Pretzel Filled Stick Extruder System, which consists of a Low Pressure Extruder and pump system that combine raw batches of dough and dough filling into a specifically shaped filled rope

For uniform sheeted pet treat products, combine the Thomas L. Green Sheeter with Gauging Stations for precise thicknesses prior to shape forming. Scrapless geometric shapes and distinct shapes can be formed by the Rotary Cutting Station.

Baking and Drying Solutions

The flexible Reading Pretzel SPECTRUM OVEN® offers a variety of heat transfer combinations in a single modular design. This single pass convection baking platform is designed for balanced and consistent baking of pet treats with operator controlled exhaust, air temperature, circulation velocity, and moisture removal rate.

Add an optional SPECTRUM Multi-Pass Dryer for faster oven speeds, greater production throughput, and more process control. The Dryer efficiently reduces product core moistures improving overall quality and storage characteristics.

Call Reading Bakery Systems at (01) 610-693-5816 or click here to contact us online to learn more about our innovative pet food processing equipment.