Reading Bakery Systems manufactures a range of innovative equipment that will meet the demands of your baked potato chips and baked crisps processing lines and enable you to produce a better finished product.

Reading Bakery Systems serves customers in the global food and bakery industries, providing high-quality systems for the production of baked potato chips, baked crisps, crackers, biscuits, cookies, pretzels, bread snacks, pet treats and more, to help them meet their unique challenges.

Mixing Solutions

Producing large quantities of uniform dough can be a challenge. Continuous Mixing offers a number of advantages over batch mixing, including the ability to produce more consistent dough with less labor and energy.

The Exact FX Continuous Mixer evenly distributes small amounts of moisture into large amounts of powder. A high-speed mixing shaft lifts powdered ingredients into and through atomized liquids sprayed into the mixing chamber.

This mixer can be used to produce potato-, corn- and rice-based products and is ideal for hydroscopic powders such as the potato flakes used to make fabricated potato chips or any other low moisture mixtures.It prevents the creation of wet and dry areas in the final dough and ensures a great texture.

The FX Continuous Mixer provides for precise and uninterrupted ingredient delivery to the mixer, eliminates the chances of dough contamination, and features dough production rates from 100 to 1,250 kg/hour.

Dough Forming Solutions

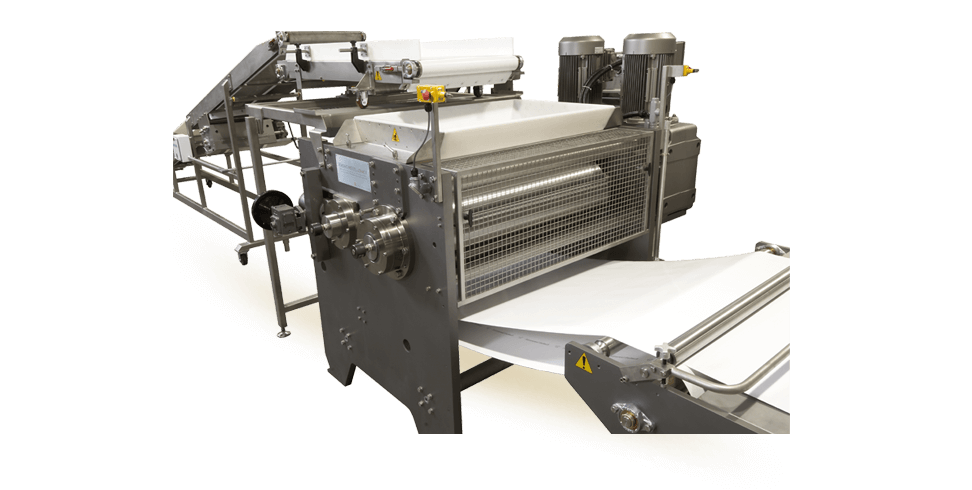

The single-reduction Thomas L. Green 2-Roll Sheeter will produce a continuous and consistent dough sheet ready for dough forming or further reduction and discharge it directly onto the Rotary Cutting Station infeed conveyor.

Sheet thickness is controlled by the distance between the two powered stainless steel rolls (which is adjustable). The rolls compress the dough into a single sheet with consistent characteristics and thickness. An optional 2-Roll Sheeter can be provided to produce chips with a ridged appearance and crinkled product texture.

The Thomas L. Green Rotary Cutting Station accurately and continuously cuts product shapes out of a single dough sheet and reroutes scrap dough to the dough handling system for reuse. This system can be designed with two die rolls to accommodate complex shape adjustment and can be quickly changed to increase product flexibility.

Baking Solutions

The Reading Pretzel SPECTRUM OVEN® is one of the world’s most advanced commercial oven systems and has helped to make us a leader in the pretzel, crisp, bread snack, and potato snack industries.

Customers benefit from a variety of heat transfer combinations in one modular design. The convection baking and drying platform is designed for balanced and consistent baking of potato chips. Operators control the product moisture removal rate for maximum quality assurance. A dryer may be combined with the oven zone to create a space efficient two-pass baking chamber.

As leading suppliers of equipment for your potato chips production lines, Reading Bakery Systems’ expertise, innovative research and development, and range of equipment are unrivaled. Call us at (01) 610-693-5816 or click here to contact us online to learn more.