When looking for stackable potato chips machinery to improve your production processes and meet growing demands for your products, Reading Bakery Systems offers high-quality, affordable solutions.

Reading Bakery Systems (RBS), headquartered in Robesonia, Pennsylvania, is a long-time leader in the snack food industry and proudly offers the world’s most advanced commercial baking systems.

We serve customers in the global food and bakery industries, providing innovative equipment and complete systems for the production of baked potato chips, baked crisps, crackers, biscuits, cookies, pretzels, bread snacks, pet treats and more, that can help them solve their unique challenges.

Visit with our team at the RBS Science & Innovation Center in Sinking Spring, Pennsylvania, where you can test your products and processes on our equipment. At this fully licensed food production facility, you can perfect your process using the most advanced technology available today.

Stackable Chip System

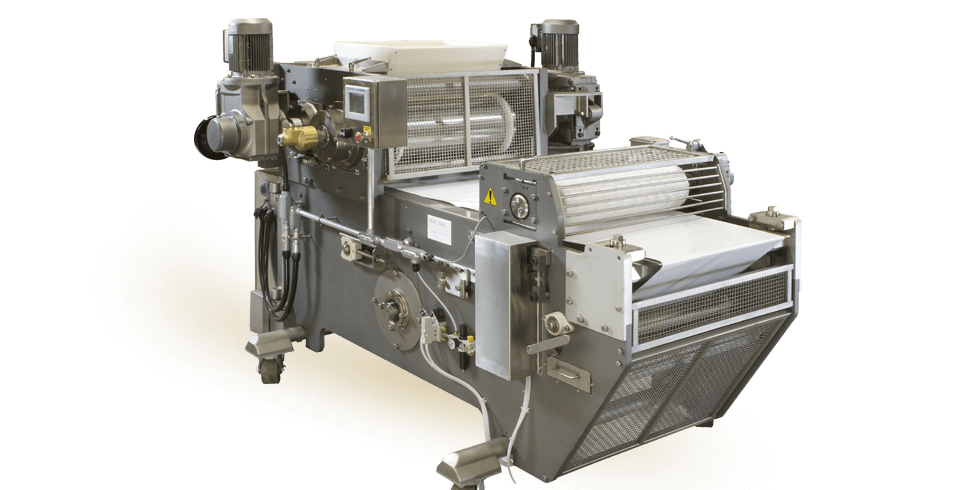

Our modular Stackable Chip System reliably and efficiently produces fabricated stackable fried chips. It includes a specialized FX Continuous Mixing System, 2-Roll Sheeter and Rotary Cutting Station and can produce between 500-1,000 kg/hr depending on the fryer capacity (fryer not supplied by RBS).

Continuous Mixing

Continuous mixing offers several advantages over batch mixing depending upon your products, processes, recipes, and other factors. The biggest advantage in all applications is the ability to produce more uniform dough and, therefore, a more consistent finished product.

Designed specifically for the stackable fried chip process, the Exact FX Continuous Mixer distributes moisture evenly throughout the potato dough by means of a specialized liquid injection system and a revolutionary mixer shaft design.

Continuous mixing minimizes the time between the mixer and 2-Roll Sheeter, eliminates batch cycle variations, and creates consistent and appealing product textures. With this recipe-driven system, final product quality is assured and is fully repeatable.

Sheeting & Cutting

Thomas L. Green 2-Roll Sheeter: The 2-Roll Sheeter creates a consistent dough sheet that is discharged directly onto the Rotary Cutter infeed conveyor. Its stainless steel rolls are manufactured to precise tolerances of concentricity in order to maintain consistent dough sheet formation and are provided with unions for chilled water supply to maintain roll surface temperatures during production.

Thomas L. Green Fabricated Chip Sheeter: This forming machine is capable of sheeting and cutting shapes from potato doughs consisting of dry premixes, potato flakes, whole grains, corn and other formulations. Dough is delivered to a hopper above two large-diameter, solid core, water-cooled sheeting rolls. In a single pass, dough is reduced and sheeted to a typical thickness of 0.7mm (.027”). Cut shapes are delivered directly into an oven or fryer (fryer not supplied by RBS) prior to seasoning and packaging.

Thomas L. Green Rotary Cutting Station: The Rotary Cutter features a die roll that separates the dough sheet into distinct shapes. It can be designed with two or more die rolls to allow a more efficient changeover between product types or sizes.

Stackable potato chips machinery from Reading Bakery Systems can handle all aspects of your manufacturing process and provide you with greater flexibility than ever before. Call us at (01) 610-693-5816 or contact us online to learn more about our equipment and turnkey systems.