Features & Specifications

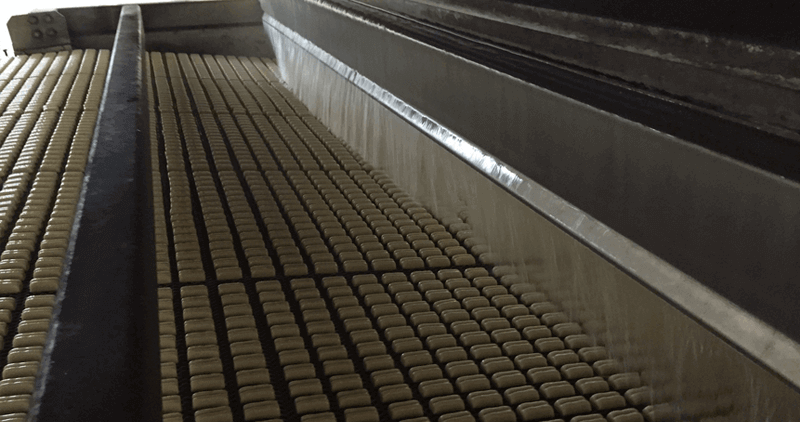

Additional Equipment Photos

See it in Action

Our cutting-edge equipment optimizes output and efficiency to improve your products and your process.

- Automatic Electronic Level Control - An electronic controller and capacitance probe is used for precise level control of the cooking solution ensuring consistent product dwell time and product quality.

- Automatic Electronic Solution Strength Control: An electronic controller and in-line probe are used for safe and accurate dosing of liquid sodium hydroxide from its storage vessel to the Cooker tank.

- Burner fires into an immersed tube for maximum surface area resulting in excellent heat transfer.

Contact us for a full list of features and specifications.

Request More InfoRBS equipment is designed and built to our SafeShield Program standards to ensure operator safety, easy and quick sanitation and food safety. Key SafeShield features for this machine are:

- Solution and waterfall components are contained behind an exhaust hood

- No operator interaction required during production

- Sanitary centrifugal circulation pump

- Hood and conveyor rack elevating system allows access for sanitation after production

Reading Bakery Systems provides the latest, custom designed control systems for your equipment. All control systems are designed and built in house. We stay up to date on the latest technologies, safety standards and control specifications to keep your production line running safely and efficiently.

- Conveyor speed and solution strength are monitored and controlled automatically

- Solution sampling valve is provided for quality control inspection

- Burner and plumbing components are operator accessible during production