Features & Specifications

Additional Equipment Photos

See it in Action

Our cutting-edge equipment optimizes output and efficiency to improve your products and your process.

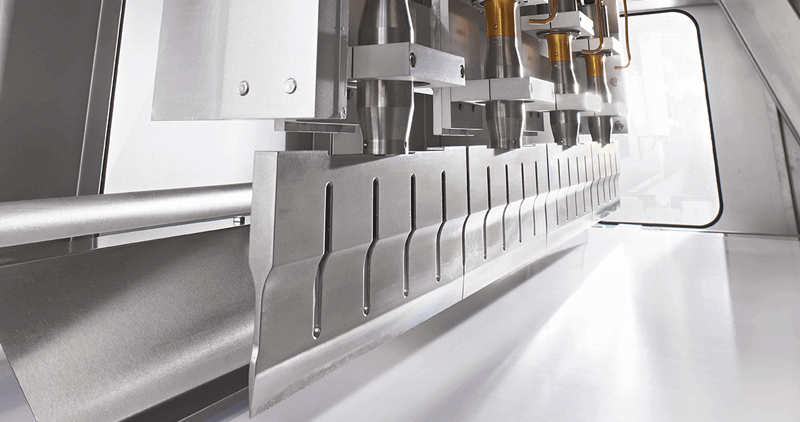

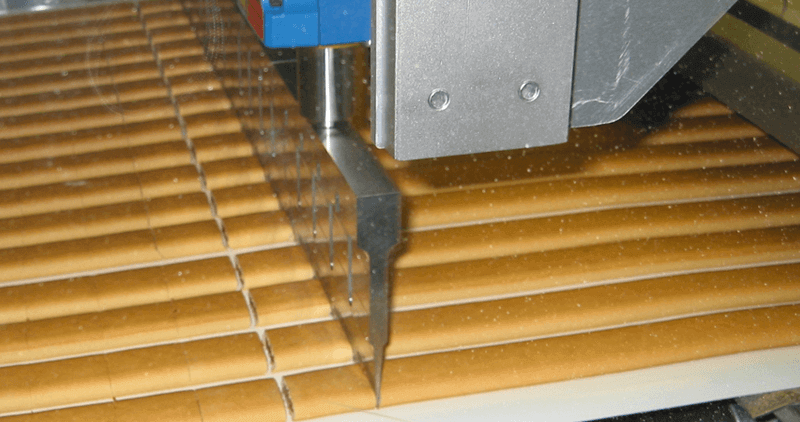

- No deformation, smearing or blade build-up due to ultrasonic high frequency vibrations

- Operator maintains control over cutting speed, length of cut and ultrasonic amplitude during production

- Cutters can be built as stand-alone machines with integrated transfer conveyors or mounted onto an existing machine.

- Operators can control the cut mode and speed from a local control panel during operation.

- Adjustable cutting profile accommodates changing production requirements.

- Can be operated in continuous mode at up to 175 cpm or in cycle mode at speeds up to 50 cpm

Contact us for a full list of features and specifications.

Request more infoRBS equipment is designed and built to our SafeShield Program standards to ensure operator safety, easy and quick sanitation and food safety. Key SafeShield features for this machine are:

- Fully automated operation maintains distance between operators and moving parts

- Emergency stops immediately stop the blade motion and transfer conveyor belts.

- Mechanically secured and electronically interlocked guards around cutting assembly

- Transfer conveyors have integrated belt scrapers

- Guards are either transparent polycarbonate or designed for ease of inspection during production

- Guarding allows observation of the cutting process while keeping operator safe

Reading Bakery Systems provides the latest, custom designed control systems for your equipment. All control systems are designed and built in house. We stay up to date on the latest technologies, safety standards and control specifications to keep your production line running safely and efficiently.

- Adjustable ultrasonic frequency to minimize sticking to blade

- Automatic control of cut speed and cutting mode

- Onboard touchscreen control interface for quick and easy adjustment