Features & Specifications

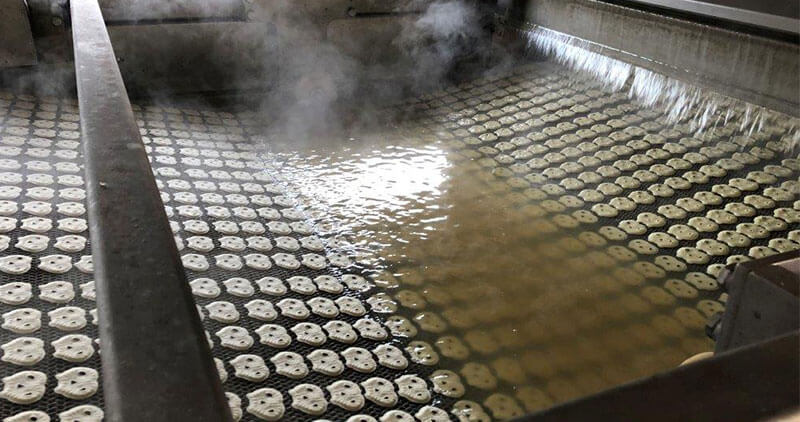

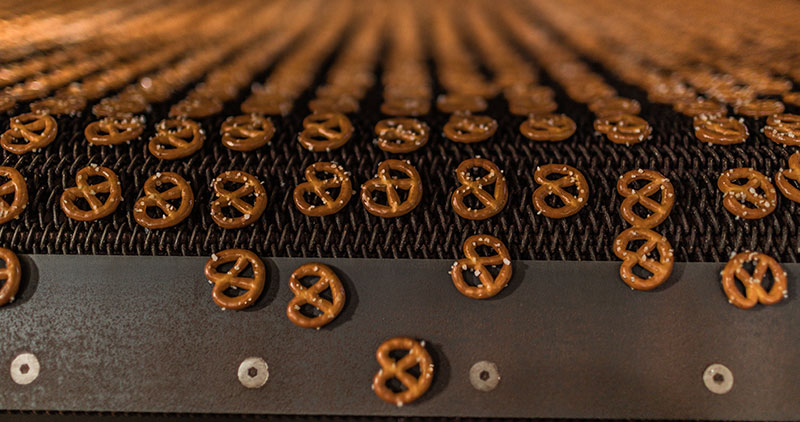

Pretzel & Snack Photo Gallery

See it in Action

Reading Bakery Systems is the world leading supplier of efficient, high volume pretzel and snack systems.

This flexible system allows you to create a variety of pretzel shapes, sticks, braids, flats, sushki, filled sticks and bread and potato snacks on one production line. Product changeover is as simple as exchanging one compression head and die for another one with a different shape.

Our production systems can be fed using a batch mixer or a continuous mixer depending on your level of automation. Continuous mixing systems from Exact Mixing are fully automated; they reduce labor, cut costs, improve consistency and simplify your mixing process. With these recipe-driven systems, final product quality is assured and is fully repeatable.

View our Extruded Die Catalog to see examples of our most popular, and most innovative designs.

Interested in Lower Production Volumes?

For customers interested in producing pretzel shapes and sticks at lower production volumes, we also offer our Vector Series Pretzel System. This system is capable of producing from 125-500 kg/hr of finished product.

Request More InfoClick the links below to learn more about available equipment for this system.

We understand the increasing demands you face to ensure safety, sanitation and compliance. Our SafeShield Program combines cutting-edge design and manufacturing practices with a firm commitment to safety and sanitation.

Safeshield Program Highlights:

- Optimize bakery equipment to meet or exceed standards for safety and sanitation

- Guard only what is necessary to maximize operator safety while minimizing potential harborages and un-cleanable areas

- Use automation to reduce employee interaction, improve safety and reduce potential for contamination of food

- Ensure equipment that contacts food can be easily and thoroughly cleaned and sanitized

- Select materials that pose the lowest risk for product contamination